Kenya Vehicle Manufacturers (KVM) has restarted the assembling of Volkswagen models as part of a renewed effort to strengthen its partnership with Germany.

The local assembler based in Thika is now producing the Volkswagen Touareg, Tiguan and T-Cross models through a Completely Knocked Down (CKD) arrangement, where vehicle parts are imported and then assembled locally.

The initiative is a significant win for Kenya and is expected to boost local production, create new jobs, and facilitate the transfer of modern automotive technology to the Kenyan market.

German Deputy Ambassador to Kenya Alexander Fierley said on Tuesday the restart of production at KVM highlighted the rekindled cooperation between Kenya and Germany in the auto industry.

During a visit to KVM, he noted that the partnership will strengthen capacity building, integrate modern production technologies and encourage eco-friendly transportation.

“The automotive industry is crucial for economic development and Germany’s partnership with Kenya aims to create stronger industry ties, promote innovation and technology transfer in order to support the country’s economic goals,” Fierley said.

Kenya Vehicle Manufacturers, which is majority-owned by CFAO Mobility Kenya, has a diverse portfolio of assembled vehicles for the Kenyan market. They include Mercedes-Benz trucks and buses as well as models from Sinotruk, Tata, Hyundai and BasiGo’s electric buses.

The addition of Volkswagen models to this line-up will further expand its multi-brand collection and reinforce Kenya’s position as the regions’ leading hub for vehicle assembly.

On his part, Arvinder Reel, the Managing Director of CFAO Mobility Kenya, stated that their investment in KVM will create more jobs, provide skills and innovation transfer from global Original Equipment Manufacturers (OEMs), support the growth of small and medium-sized enterprises through local content and offer more reasonably priced vehicles to Kenyan consumers.

The partnership renewal is expected to attract more investment and encourage other manufacturers to start local assembly in alignment with the government’s goal of developing the automotive sector under its industrialisation agenda.

KVM began assembling the Polo Vivo in 2016, later adding the Caddy and the five-seater Tiguan to its production line.

In March this year, the plant expanded its offerings to include the seven-seater Tiguan Allspace, making it the fourth vehicle to be locally assembled in Kenya.

- A Tell Media / KNA report by Hellen Lunalo

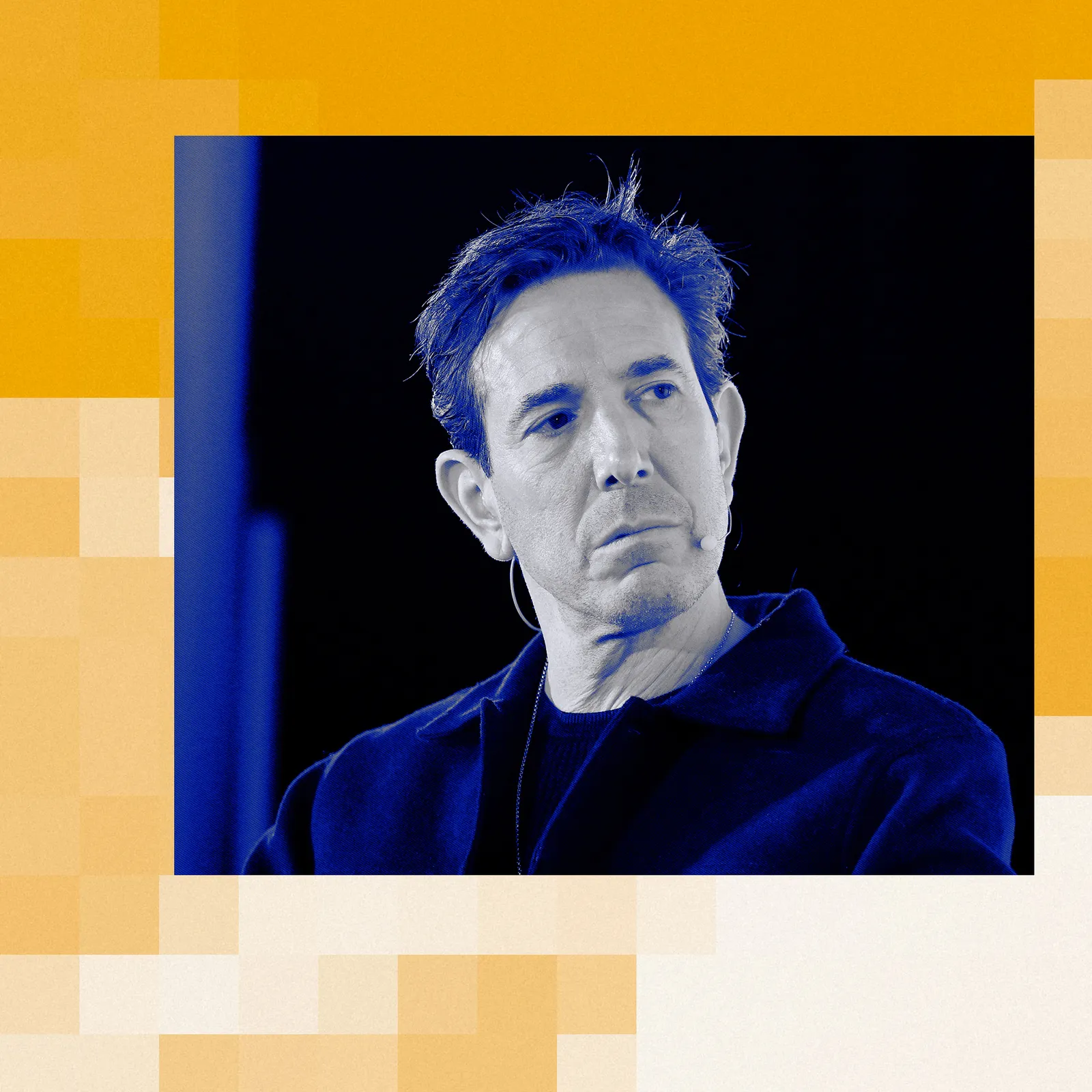

From Left CFAO Mobility Managing Director Arvinder Reel, Economic Affairs, Economic Cooperation & Development, German Embassy Pius Ogola Ongoo, Alexander Fierley (Economic Affairs, Economic Cooperation & Development German Embassy) and the General Manager, Kenya Vehicle Manufacturers, Moses Abiero during the visit to KVM.

The same team during the visit to KVM.